METHODOLOGY FOR FIRE WATER SYSTEM ADEQUACY STUDY (FWSAS)

The primary objective of a Fire Water System Adequacy Study (FWSAS) is to evaluate the effectiveness, reliability, and sufficiency of a facility’s fire water system. This includes ensuring the system can deliver adequate fire protection in compliance with safety standards, while identifying areas for improvement. The study focuses on assessing whether the system: Provides sufficient water supply and pressure to combat fires, Is reliable, with backup systems in place, Meets local and international fire safety regulations, And highlights deficiencies for potential upgrades or maintenance.

METHODOLOGY FOR HAZARD OPERABILITY (HAZOP) STUDY

The purpose of HAZOP Study is to identify the hazard and operability problems and to reduce the probability and consequences of an incident in the process facilities that would have a detrimental impact to the personnel, plant, properties, environment and company reputation. This Method describes the organization, study methods and recording requirements for HAZOP studies. Its purpose is to advise both HAZOP team members and other members of a project, of the approach to be adopted as well as the other contributions required from individuals. It is based upon considered worldwide best practices and international benchmarks in HAZOP deployment and management.

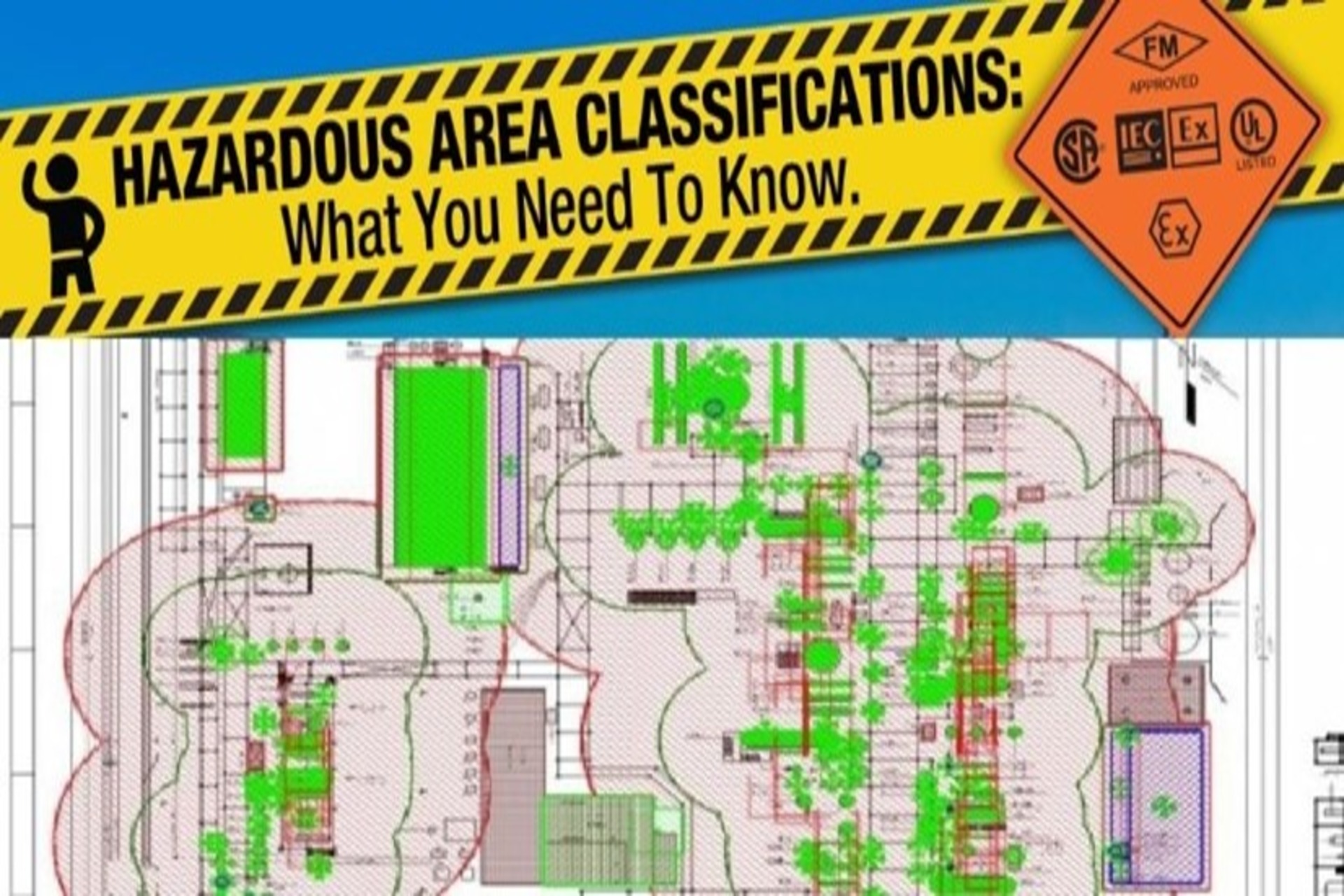

METHODOLOGY FOR HAZARDOUS AREA CLASSIFICATION (IEC)

The purpose of the Hazardous Area Classification study is to determine the extent of the hazardous areas around equipment handling or storing flammable fluids, combustible fluids and combustible dusts, both liquid and vapors in terms of Zone 0/20, Zone 1/21, Zone 2/22 The aim of hazardous area classification is to avoid ignition of those releases that may occur from time to time in the operation of facilities handling flammable liquids and vapors. The approach is to reduce to an acceptable minimum level the probability of coincidence of a flammable atmosphere and an electrical or other source of ignition occurring. In Hazardous Area Classification the extent of the hazardous areas around equipment handling or storing flammable fluids, both liquid and vapors is determined in terms of Zone 0, Zone 1, and Zone 2. The hazardous area classification around the equipment handling flammable/explosive dust is determined in terms of Zone 20, Zone 21, and Zone 22.

METHODOLOGY FOR HAZARDOUS AREA CLASSIFICATION-IS

The purpose of the Hazardous Area Classification study is to determine the extent of the hazardous areas around equipment handling or storing flammable fluids, combustible fluids and combustible dusts, both liquid and vapors in terms of Zone 0, Zone 1, Zone 2 and Division 1 and Division 2

METHODOLOGY FOR HAZARDOUS AREA CLASSIFICATION-NFPA

The purpose of the Hazardous Area Classification study is to determine the extent of the hazardous areas around equipment handling or storing flammable fluids, combustible fluids and combustible dusts, both liquid and vapors in terms of Zone 0, Zone 1, Zone 2 and Division 1 and Division 2

METHODOLOGY FOR F&G

This involves collecting data and identifying scenarios through detailed review of project documents such as Process Flow Diagrams (PFD), Piping and Instrumentation Diagrams (P&ID), and Plot Plans. It also includes identifying hazardous materials present in the project facility. This step involves conducting assessments to determine the dispersion of flammable gas (at 25% LFL and 50% LFL), fire scenarios (jet/pool fire), radiation distances (12.5 kW/m²), and toxic distances (10 ppm and 20 ppm). The specific assessment criteria will be finalized in agreement with the client. In line with the existing Fire and Gas (F&G) zones, an F&G mapping study will be conducted.