DISCLAIMER

HSE

Risk Management Services Private Limited accepts no liability or responsibility

whatsoever for it in respect of any use of or reliance upon this Methodology by

any third party.

Copying this Methodology without the permission of HSE Risk Management Services Private Limited is not permitted.

The objective of vent

sizing for storage tanks is to prevent over-pressurization or vacuum conditions

inside the tank, ensuring safe operation and environmental protection.

2. Guidelines Used

· API

2000 Venting Atmospheric and Low-Pressure Storage Tanks

· NFPA

30 Flammable and Combustible Liquid Code

· Normal

Venting: The venting required because of

operational requirements or atmospheric changes.

· Nm3/h:

Normal cubic meters of air or gas per hour at a temperature of 0°C and pressure

of 1.014 bar.

· Thermal

inbreathing: The movement of air or

blanketing gas into a tank when vapors in the tank contract or condense as a

result of weather changes conditions (e.g., a decrease in atmospheric

temperature).

· Thermal

outbreathing: The movement of vapors out of a

tank when vapors in the tank expand and liquid in the tank vaporizes as a

result of weather changes (e.g., an increase in atmospheric temperature).

·

Vent Sizing concept

The normal vent sizing requirements are based on normal

venting requirements due to liquid movement in or out of the tank and thermal

breathing requirements. In this report breathing requirements due to fire

exposure or any other emergency situation is not considered. Inbreathing

results when liquid is moved out of the tank and from contraction or

condensation of vapor caused by decrease in vapor space temperature (thermal

breathing). Outbreathing results when liquid is moved into the tank, maximum

vaporization caused by such Inflow and from expansion and vaporization that

result from increase in vapor space temperature (thermal breathing).

As per API 2000: Venting Atmospheric and Low-Pressure

Storage Tanks, the total normal venting capacity shall be at least the sum of

the venting requirements for liquid movement and thermal effect. The process

involves the calculation of breathing requirements due liquid movement and

thermal effects and adding them up to get total breathing requirements. NFPA 30 also states that “Normal vents shall

be sized in accordance with either API Standard 2000, Venting Atmospheric and

Low-Pressure Storage Tanks, or another accepted standard. Alternatively, the

normal vent shall be at least as large as the largest filling or withdrawal

connection but in no case shall it be less than 32 mm (1.25 in.) nominal inside

diameter”.

·

Vent

Sizing Steps

The following sequence of activities is implemented during

the Vent Sizing Calculation for outbreathing of storage tanks only.

Ø

Calculation

of venting requirements from API 2000 Table 1B—Normal Venting Requirements. And

Table 2B —Requirements for Thermal Venting Capacity.

Ø

Summation

of both the venting requirements to get total venting capacity required.

Ø

Now

using the formula given in Section 4.6.1.2 of API 2000 to calculate area

required.

Ø

If

the area is less than largest filling or withdrawal connection, the area of

vent pipe is decided according to Statement given in NFPA 30 as described in

Section 2.2 Vent Sizing process.

4.1.

Data

Requirement

Ø Equipment

P&IDs

Ø Equipment

Specification sheet

Ø Pump

Details like Head, Flow rate

Ø MSDS

of Chemicals

Ø Google

Earth Location of facility

4.2.

Project

Deliverables

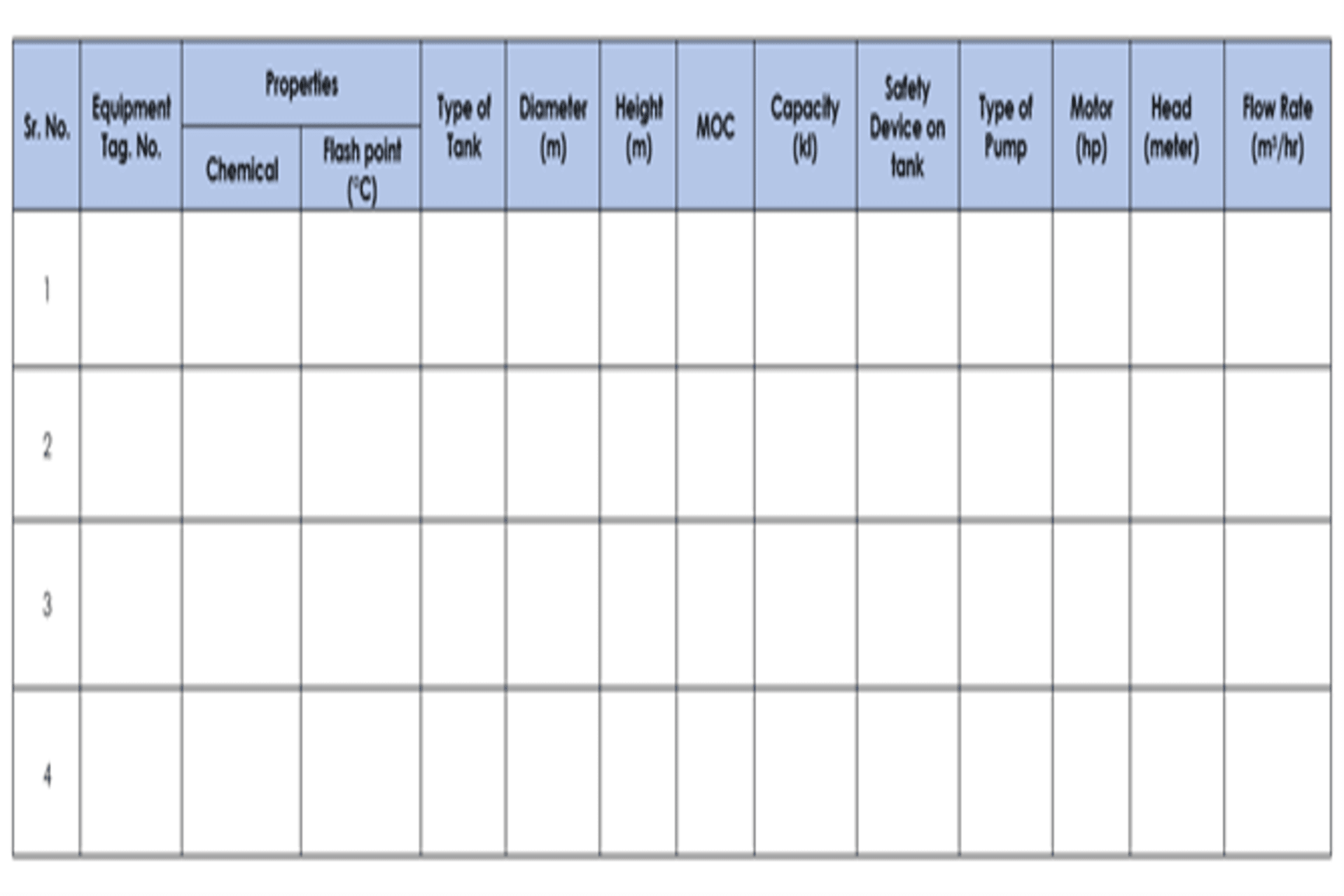

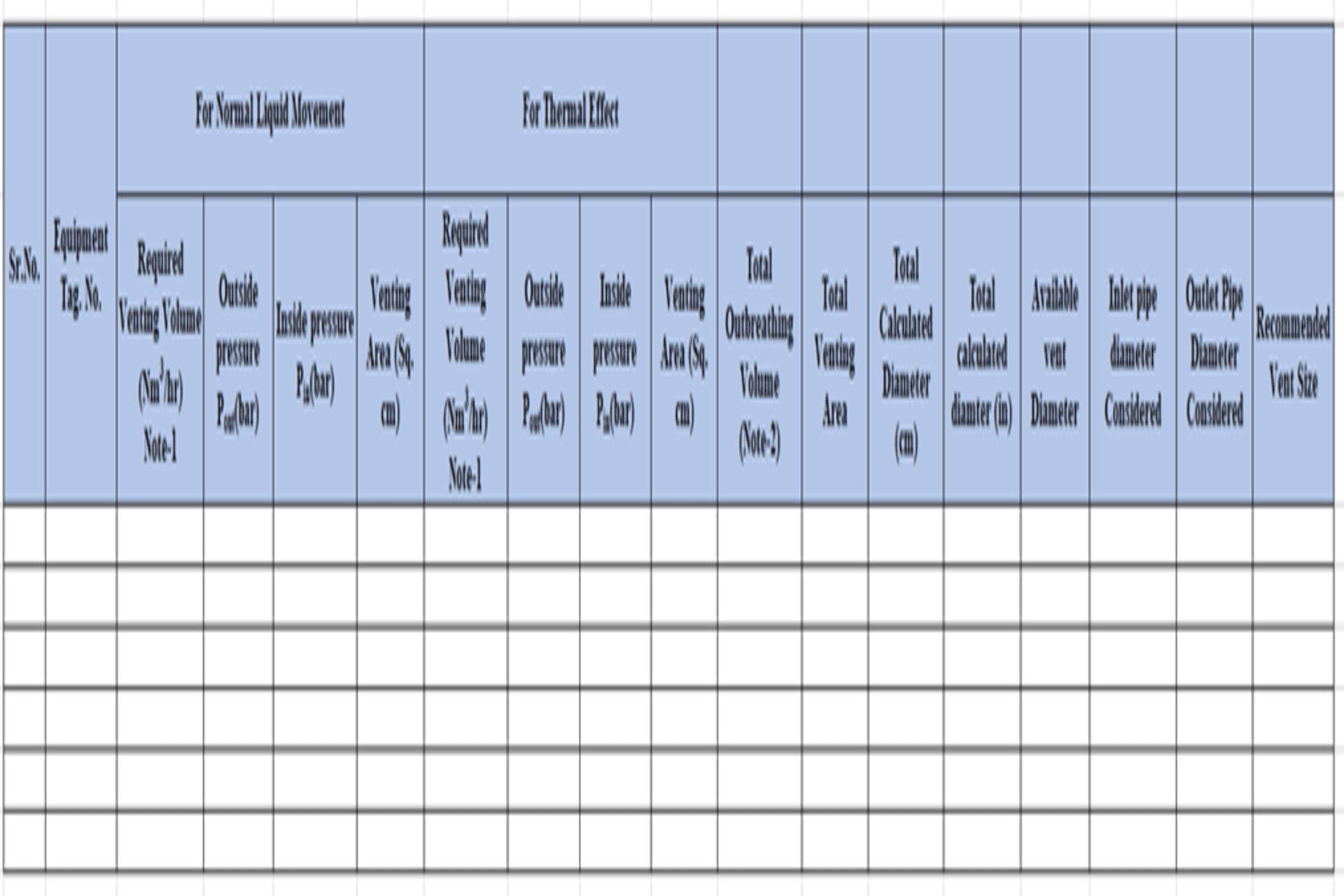

Table 1: Storage Tank/Vessels -Vent Sizing Study

|

Sr. No. |

Document Deliverable |

|

1. |

Executive

Summary |

|

2. |

Vent

Sizing Methodology |

|

3. |

Assumptions |

|

4. |

|

|

5. |

Conclusion |

|

6. |

Site

observation Details |

|

7. |

Reference |

|

8. |

Vent Sizing Calculation Worksheet |

4.3.

4.4.

Vent

Sizing Calculation Worksheet Format

4.5.

Software

Used

The Vent Sizing

calculation is done using Microsoft Excel. The formula for calculating area is

taken from API 2000 and fed to MS Excel for repetitive calculation.