1. Objective

To

achieve and maintain inert atmosphere using nitrogen (N2) inertization in the

storage tank, ensuring safe storage conditions and preventing the risk of

combustion or oxidation of stored materials.

2. Guidelines Used

·

API 2000 Venting

Atmospheric and Low-Pressure Storage Tanks

·

NFPA 69

·

Normal Venting:

The venting required because of operational requirements or atmospheric

changes.

·

Nm3/h:

Normal cubic meters of air or gas per hour at a temperature of 0°C and pressure

of 1.014 bar.

·

Thermal inbreathing:

The movement of air or blanketing gas into a tank when vapors in the tank

contract or condense as a result of weather changes conditions (e.g., a

decrease in atmospheric temperature).

· N2

Inertization concept

The volume of

nitrogen gas required to inertize the tank during its operation depends on the

volume of inbreathing gas while the liquid is moved out of the tank and the

vapours condense or contracts in tank due to atmospheric temperature changes.

N2 inertization of tanks is done to provide inert atmosphere in storage tanks

storing flammable, combustible or reactive liquids. The volume of N2 required

under normal operating conditions is almost equal to the volumetric rate of

liquid discharge from the tank. However, due to sudden atmospheric changes and

temperature drops the vapour present in storage tanks contracts and condense

leading to vacuum and more Nitrogen requirement to fill up the vacuum space

generated. This factor is covered under thermal breathing requirements of tank.

As per API, calculations for thermal breathing requirements is based on

temperature drop of 37.8 °C within 1 hour.

As per API 2000:

Venting Atmospheric and Low-Pressure Storage Tanks, design of nitrogen

inertization system depends on the total normal inbreathing capacity which is

the sum of the inbreathing requirements for liquid movement and thermal effect.

During inbreathing nitrogen is provided instead of air to achieve an inert

atmosphere withing the storage tank. The Nitrogen supply line is connected to

the Storage Tank via Breather valve. As the liquid in the tank is pumped out or

drained or due to contraction or condensation of vapours inn storage tanks,

vacuum will be created which will trigger breather valve to open and let

nitrogen gas to occupy the vacuum space. The tank will be maintained at

atmospheric pressure with help of breather valve opening to provide nitrogen to

protect the tank against any vacuum while maintaining inert conditions.

· Process

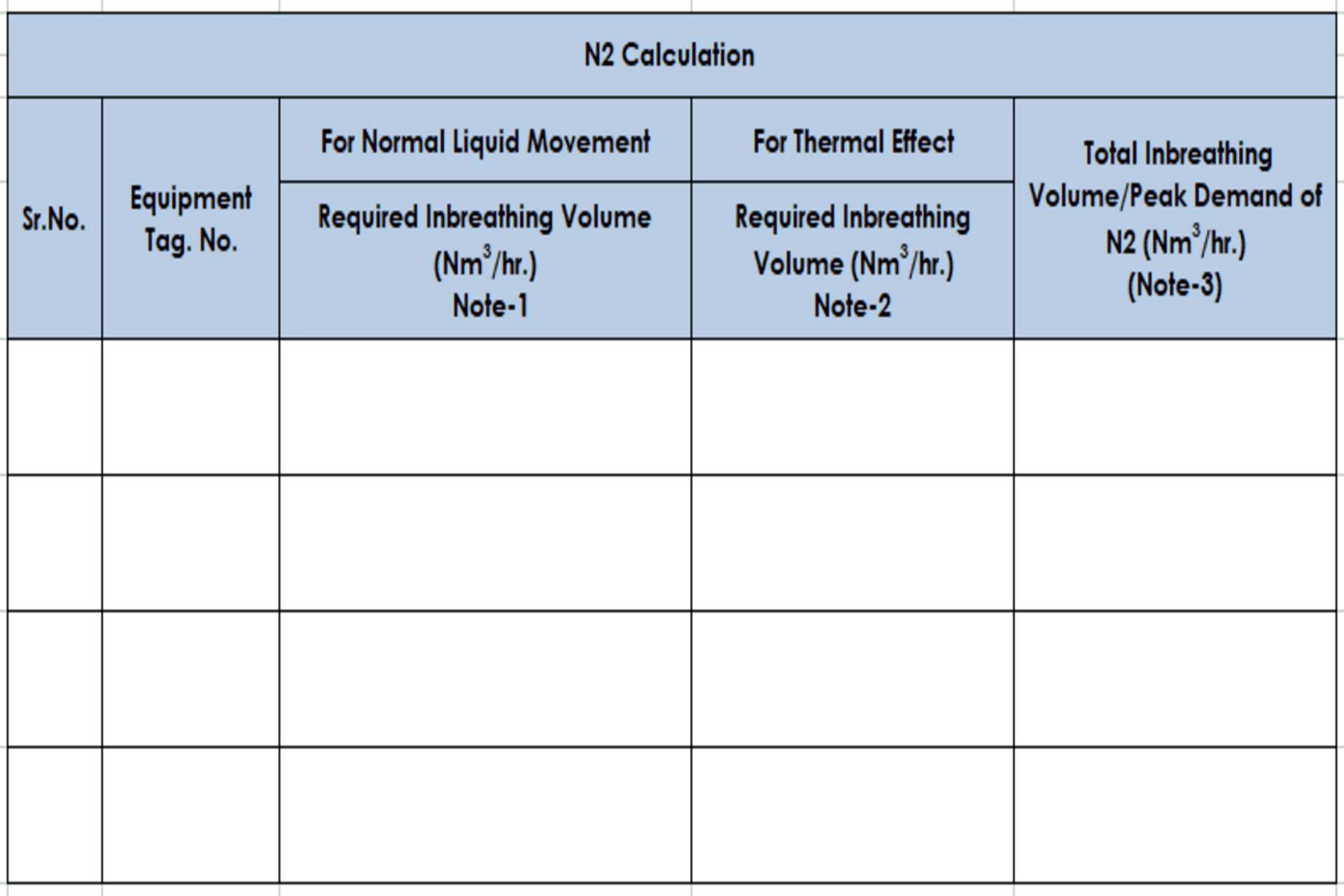

Calculation for N2 Inertization

The following

sequence of activities is implemented during the N2 inertization calculation

for inbreathing of storage tanks only.

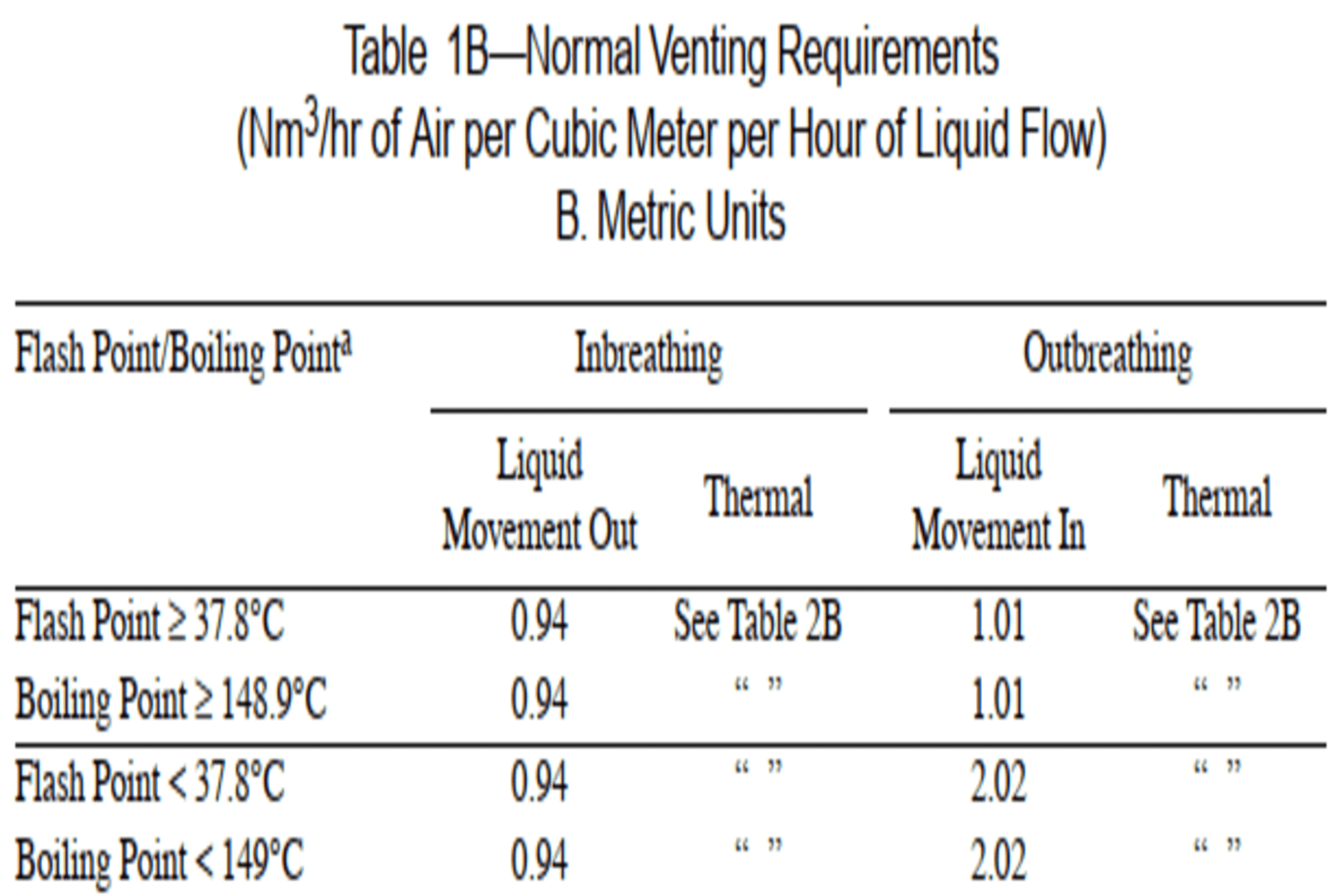

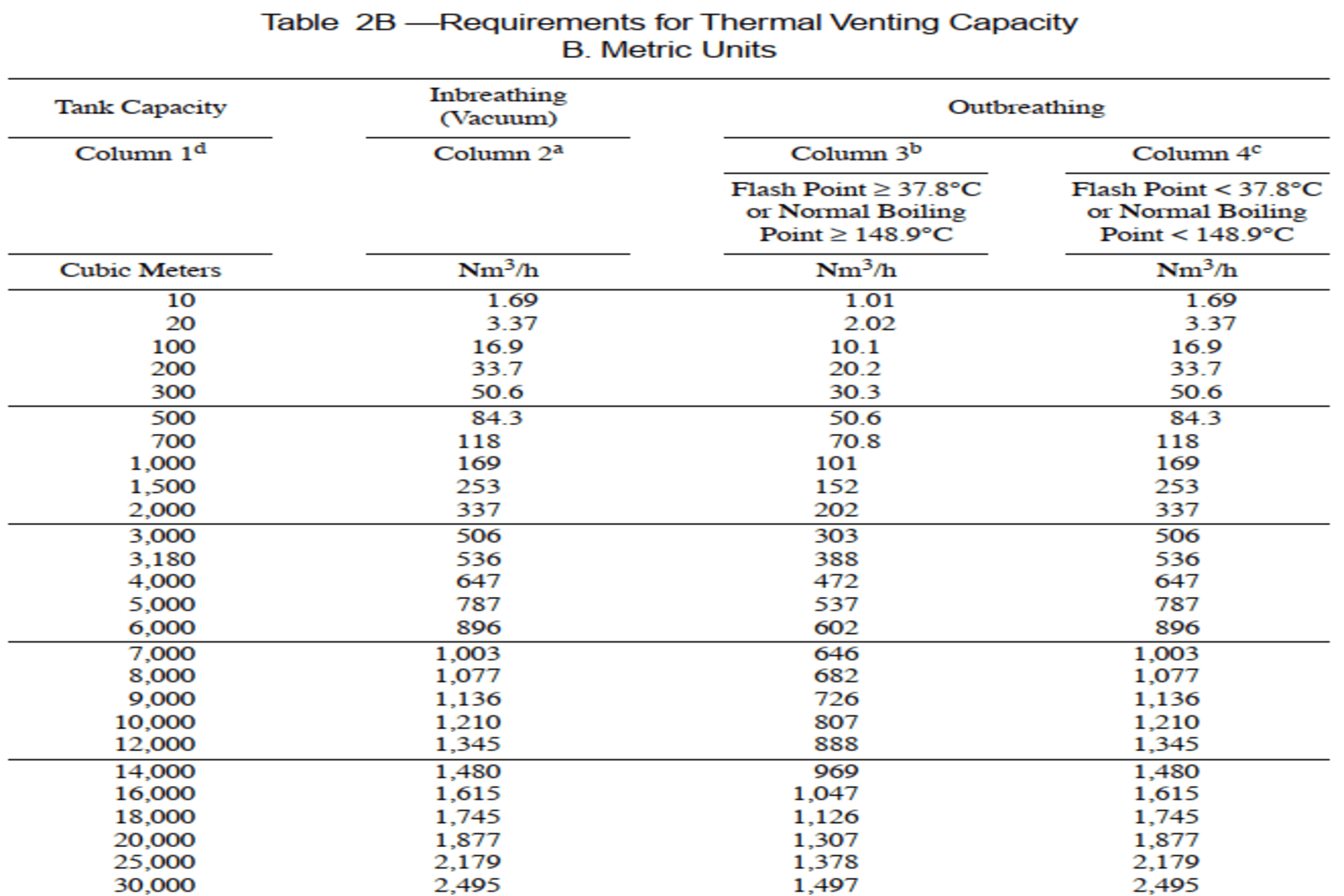

1. Calculation of inbreathing requirements is carried out from API 2000 Table 1B—Normal Venting Requirements. And Table 2B —Requirements for Thermal Venting Capacity.

i.

Determine the Flash

Point or Boiling Point of Liquid that is stored in the Storage Tank. If both

the flash point and boiling points are known then use flash point. On the basis

of flash point of liquid that is stored in tank choose an appropriate factor

under liquid movement out under inbreathing as per Table-1B.

ii.

Determine pump

flowrate responsible for Liquid Movement Out of Tank. The multiplication of

factor chosen in step (i) and pump flow rate shall give the Inbreathing

requirement for Liquid Movement Out of tank.

Example

calculation:

·

Flash Point of Liquid

Stored In tank = 9.7 °C.

·

Inbreathing

Requirement per m3/hr of Liquid Flow = 0.94 Nm3/hr

·

Amount of Liquid Flow

= 5 m3/hr

· Inbreathing Requirement for Liquid Flow of 5m3/hr = 0.94*5 Nm3/hr = 4.7 Nm3/hr.

i.

Thermal Inbreathing

requirements are based on Tank Capacity. Determine Tank Capacity and its

Inbreathing requirement as per column 2a, Table-2B

ii.

For Intermediate

values of tank capacity, use interpolation method to find Inbreathing

requirement.

Example calculation:

·

Tank with capacity of

25kl = 25m3.

·

25m3

according to table is more than 20m3 and less than 100m3.

·

Unit Inbreathing

requirement between 20m3 and 100m3 is (16.9-3.37)/(100-20)=0.169125

·

Inbreathing

requirement for 5m3 = (0.169125*5) = 0.845625

· Inbreathing Requirement for 25m3 (20m3+5m3) = (3.37+0.845) = 4.215625 Nm3/hr

2.

The inbreathing

volume due to normal breathing requirements will give volume of nitrogen

required when liquid is pumped out of the tank and thermal breathing

requirements will give volume of nitrogen required due to temperature changes.

3.

Under normal

operating conditions nitrogen requirement will be calculated as in Step 1,

Normal Inbreathing requirement due to liquid movement out and Summation of both

the inbreathing requirements that is normal and thermal to get maximum

inbreathing volume of Nitrogen which may arise if temperature drops by 37.8 °C

within 1 hour during liquid outflow from the tank.

4.1.

Data

Requirement

Ø Equipment

P&IDs

Ø Equipment

Specification sheet

Ø Pump

Details like Head, Flow rate

Ø MSDS

of Chemicals

Ø Nitrogen upstream Details and Nitrogen Purity Level

4.2.

Project

Deliverables

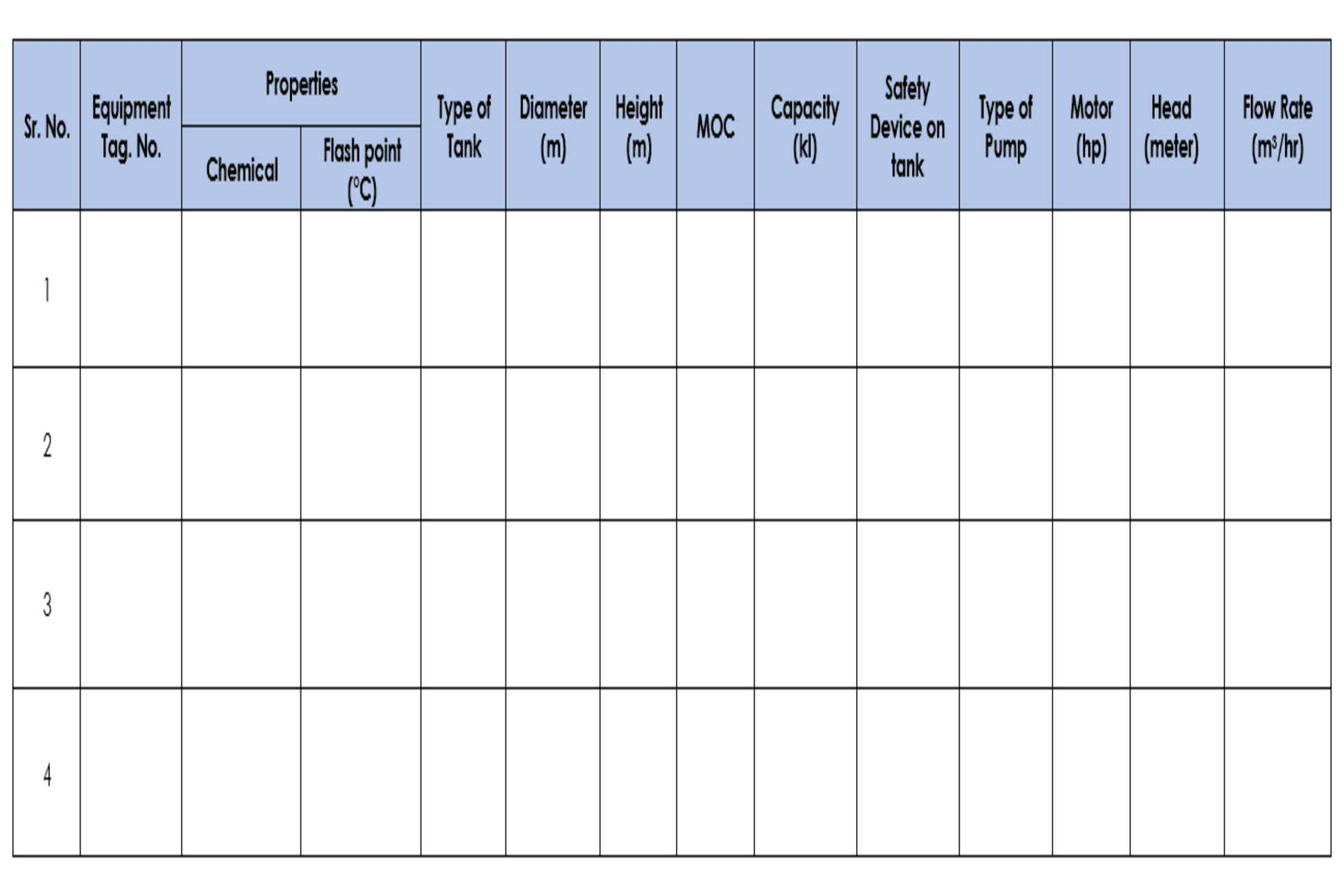

Table 1: N2 Inertization Study

|

Sr. No. |

Document Deliverable |

|

1.

|

Executive Summary |

|

2.

|

N2 Inertization Methodology |

|

3.

|

Assumptions |

|

4.

|

|

|

5.

|

Conclusion |

|

6.

|

Site observation Details |

|

7.

|

Reference |

|

8.

|

N2

Inertization Calculation Worksheet |

4.3 Site Visit Details Format

4.4 Vent

Sizing Calculation Worksheet Format

4.5 Software Used

The N2

Inertization calculation is done using Microsoft Excel.