Aditya Birla Grasim Industries Ltd. – Chemical Division, Karwar

Project Number: 25-743.02.166-gil-kawr-saau

Safety Audit Study Serial Number: 166

Project Overview :

A comprehensive Occupational Safety and Health (OS&H) Safety Audit was conducted at the Caustic Soda Plant, Phosphoric Acid Plant, and Boiler facilities of Aditya Birla Grasim Industries Ltd., Chemical Division, Karwar, in accordance with IS 14489:2018 Code of Practice on Occupational Safety and Health Audit. The objective of the audit was to systematically evaluate the effectiveness of the existing safety management systems and identify potential hazards associated with the handling of hazardous chemicals and highpressure boiler operations. The audit focused on assessing compliance with statutory requirements, identifying gaps in implementation, and recommending practical measures to enhance workplace safety and operational reliability. The study involved review of critical documents, site inspections, and interaction with multidisciplinary plant teams to assess safety performance across operational, maintenance, and utility areas.

Objective

The objective of the Safety Audit was to proactively identify deficiencies in the Occupational Safety and Health management system and assess management controls across the Caustic Soda, Phosphoric Acid, and Boiler operations, with the aim of reducing risks to personnel, plant assets, and operations.

The audit also aimed to ensure compliance with statutory provisions under hazardous chemical regulations and support continuous improvement of safety practices through structured evaluation and follow-up.

Methodology

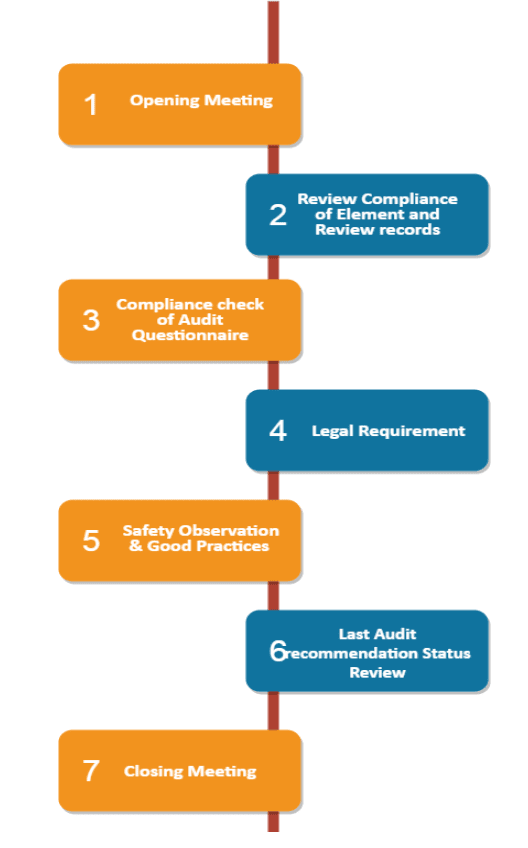

The overall methodology followed during audit is as below:

The audit observations, recommendations and elements compliance report were discussed in the meeting

Opening Meeting

The audit scope, objective, methodology and audit schedule was discussed by auditors with auditee during opening meeting.

The manufacturing process and existing OS & H system was explained by auditee to auditors

Examination

Compliance review of all 76 elements of occupational safety and health system (OS & H) of IS-14489. Wherever applicable, Procedure/ Guideline/ Document, Training matrix, MIS, Compliance Audit is reviewed of each Element.

34 nos. of Records review as per IS:14489

Compliance check of Audit Questionnaire

Review License as per applicable Legal Citation

Review the opening/ closing status of Last Audit recommendation

Site Round

Site round in various department for observing any lagging and good practices implemented by Organization

Closing meeting

Closing meeting was carried out after completion of the audit.

- Key Outcomes

Initial audit findings highlighted several areas requiring improvement across documentation, implementation, and monitoring of OS&H elements. With existing controls, many risks were adequately managed; however, some gaps were identified that warranted additional corrective measures.

Key outcomes of the Safety Audit included:

- Improved clarity on OS&H system effectiveness across hazardous chemical and boiler operations

- Identification of improvement areas to further reduce occupational and process safety risks

- Validation of good practices and management commitment toward safety

- A structured action plan to address audit observations and track closure

- Conclusion

The Safety Audit demonstrated the effectiveness of a systematic, standards-based audit approach in identifying occupational safety and health risks within complex chemical and boiler operations. By aligning the audit with IS 14489:2018 and statutory hazardous chemical requirements, the study provided a proactive assessment of safety performance and clear guidance for continuous improvement.

This case study highlights the importance of independent safety audits, multidisciplinary participation, and structured follow-up in achieving safe, compliant, and reliable operations at Aditya Birla Grasim Industries Ltd., Chemical Division, Karwar.