Project Number: 24-702.03.22-tgcipl-cot_qra

QRA Study Serial Number: 22

- Project Overview

A Quantitative Risk Assessment (QRA) Study was conducted to assess the risk level of the storage tanks, due to loss of containment and provide recommendations to reduce/ maintain the risk in ALARP/ acceptable regions at Tagros Chemicals India Pvt. Ltd., Cuddalore, Tamil Nadu, in accordance with Quantitative Risk Assessment CPR 18 E (Purple book), Committee for the prevention of Disaster, Netherlands. The objective was to determine the consequence impact and assess the risk on employees and surrounding public. Given the nature of chemicals handled, Tagros Chemicals India Pvt. Ltd. prioritizes safety to mitigate risks associated with storage and handling, ensuring compliance with regulatory standards while maintaining operational efficiency

The study involved analysis of critical project documents like Piping and Instrumentation diagrams (P&IDs), Site Layout, Site Meteorological conditions, Standard Operating Procedures (SOPs), Inventory Data, Site and Surrounding Demographic Data etc.

- Objective

The objective of the QRA study is to

- Determine the consequence impact due to various loss of containment of chemicals stored in storage tanks in tank farm of the Facility.

- Assess the risk on employees and surrounding public

- Methodology

QRA Preparation

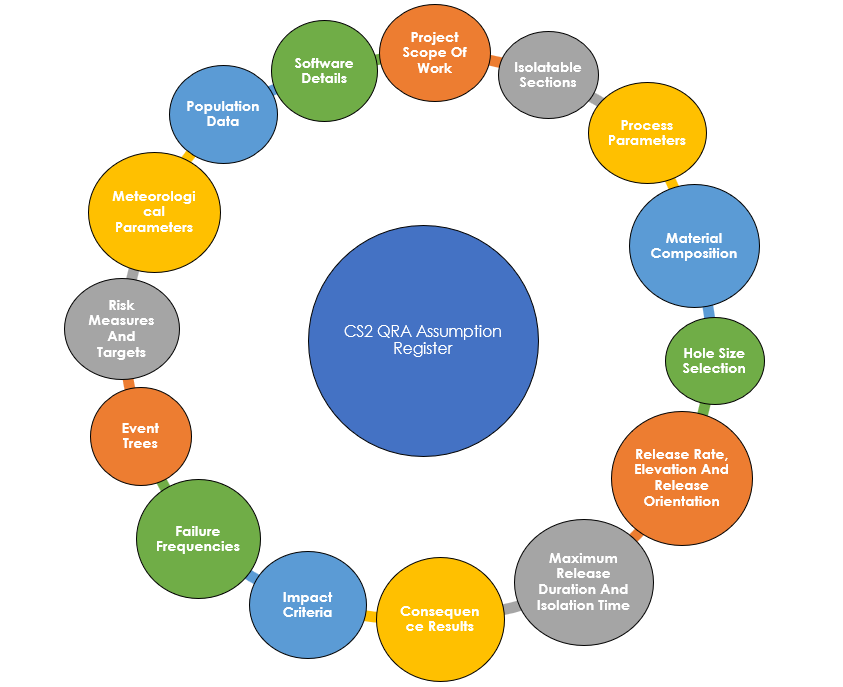

Prior to the modelling and Simulation for the QRA Study, all the relevant and essential data was requested by the HSE-RMS team. Upon receipt of the data, the HSE-RMS team analysed the adequacy of the data and prepared assumptions register. This Assumption Register lists down all the essential parameters and assumptions that were used in the consequence modelling. This Assumption Register was reviewed and approved by Tagros team before the consequence modelling. Assumption Register covers the following topic:

QRA Consequence Modelling Session

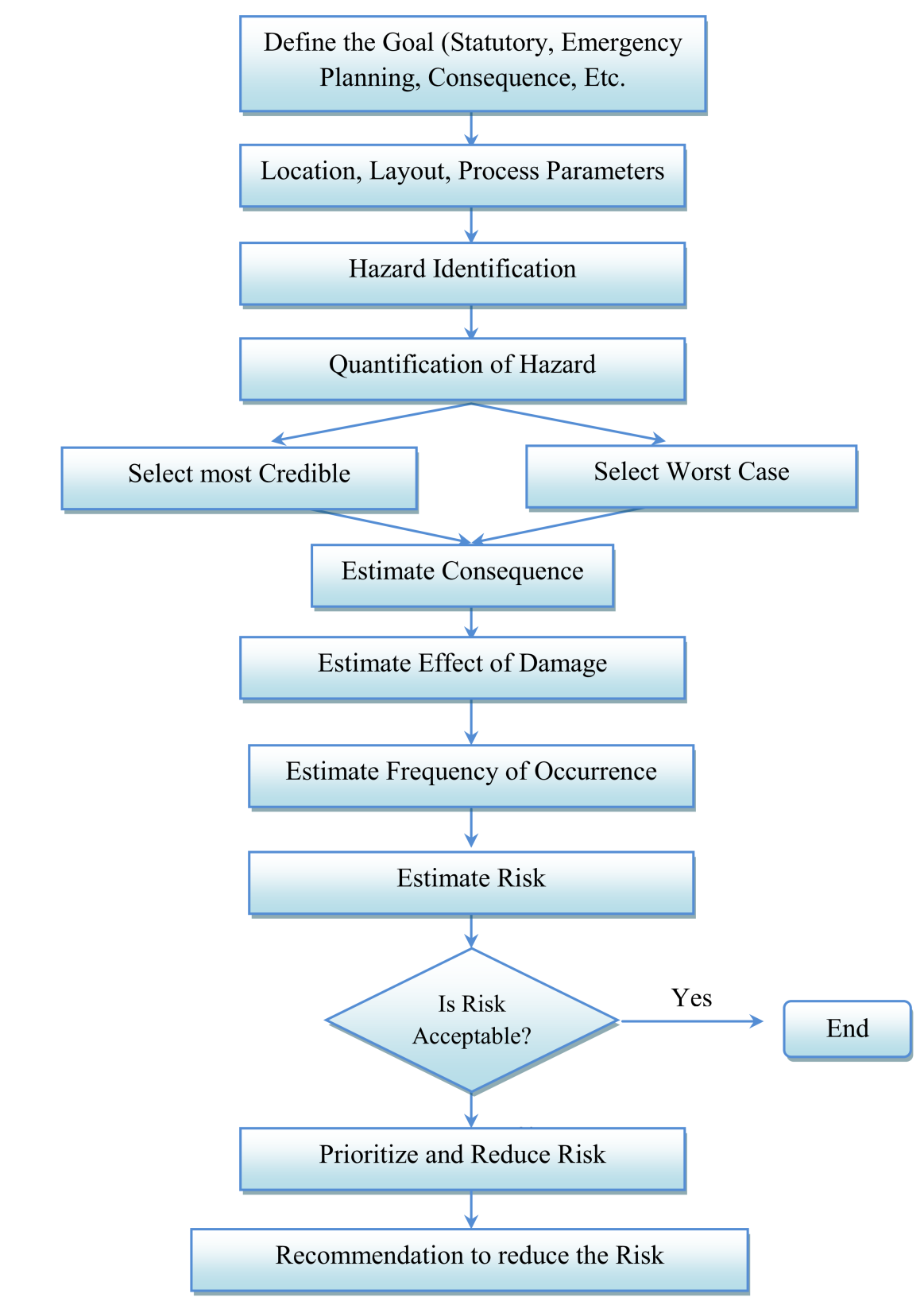

HSE-RMS utilized a structured approach in conducting the QRA:

- Hazard Identification: Identified potential hazards related to the storage and handling of chemicals, considering their properties, storage conditions, and operational practices.

- Risk Assessment: Quantitatively assessed the likelihood and consequences of identified scenarios such as leaks, spills, or fires involving hazardous chemicals using advanced modeling techniques.

- Safety System Evaluation: Evaluated the effectiveness of existing safety systems including fire detection, suppression systems, and emergency response procedures.

- Risk Mitigation Measures: Developed and recommended specific mitigation measures to reduce identified risks to an acceptable level, considering Tagros operational requirements and safety standards.

The consequence modelling started with model selection in SAFETI software developed by DNV such as pressure vessels, atmospheric storage tanks etc. After selection of appropriate models, input parameters such as volume, vessel dimensions, inventory, temperature, pressure, etc. was provided to the software. Also, other parameters such as meteorological conditions were entered.

After input of all the process parameters, demographic data was also provided in the software highlighting populations points both on-site and off-site using satellite image of the facility and surrounding area with scale. The model was made to run with the input data provided and various results such as jet fire, pool fire, flash fire, Boiling Liquid Expanding Vapor Explosion (BLEVE), Gas Dispersion, etc. was extracted from the software for the assessment.

Based on the following criteria the consequence data was assessed and conclusions were made:

- The lethality of a jet fire and pool fire is assumed 100% for the people who are caught in the flame. Outside the flame area, the lethality depends on the heat radiation distances.

- For the flash fires, lethality is taken as 100% for all the people caught outdoors and for 10% who are indoors within the flammable cloud. No fatality is assumed outside the flash fire area.

- Overpressure more than 0.5 bar corresponds approximately with 50% lethality.

- An overpressure above 0.3 bar would result in 10% fatalities.

- An overpressure less than 0.1 bar would not cause any fatalities to the public.

- 100% lethality is assumed for all people who are present within the toxic cloud.

Table 1 : Damages to human life due to heat radiation

| Exposure Duration | Radiation energy

(1% lethality), kW/m2 |

Radiation energy (2nd degree burns), kW/m2 | Radiation energy (1st degree burns), kW/m2 |

| 10 sec | 21.2 | 16 | 12.5 |

| 30 sec | 9.3 | 7.0 | 4.0 |

Table 2 : Effects due to incident radiation intensity

| Incident Radiation (Kw/m2) | Type of Damage |

| 0.7 | Equivalent to Solar Radiation |

| 4.0 | Sufficient to cause pain within 20 sec. Blistering of skin (first degree burns are likely) |

| 12.5 | Minimum energy required for piloted ignition of wood, melting plastic tubing etc. |

| 37.5 | Heavy Damage to process equipment |

Table 3 : Damage due to overpressures

| Peak Overpressure | Damage Type | Description |

| 0.50 bar | Heavy Damage | Major damage to plant equipment structure |

| 0.30 bar | Moderate Damage | Repairable damage to plant equipment and structure |

| 0.1 bar | Significant Damage | Shattering of glass |

Challenges: Challenges encountered during the QRA process included:

- Ensuring accurate data availability on chemical properties, storage conditions, and operational procedures.

- Coordinating with Tagros team to ensure compliance with safety standards and regulations.

- Balancing safety enhancements with operational efficiency to minimize disruptions.

Key distinctive characteristics of QRA:

- QRA was carried using SAFETI software developed by DNV which is internationally accepted and followed.

- Guidelines for Quantitative Risk Assessment CPR 18 E (Purple book), Committee for the prevention of Disaster, Netherlands has been used which is widely followed.

- Detailed Consequence Modelling Results were provided which are easy to understand and also Analysis of each of the consequence results were provided.

- Easily understandable Contours, F-N Curve and IRPA results were provided along with their analysis.

- Potential Explosion Sites were identified throughout the facility using TNO multi-energy explosion modelling.

- Major Risk Contributors were identified to on-site as well as off-site public.

- Key Outcomes

- The Individual Risk Per Annum (IRPA) for some equipment and activities within the defined scope exceeded the ALARP region, hence appropriate risk reduction measures were recommended.

- Offsite (public)/Societal risk levels shows a mixed trend, with initially falling under unacceptable region, but later moved to ALARP and acceptable region, also, appropriate risk reduction measures were recommended.

- Acetonitrile and Bromine are the major risk contributors.

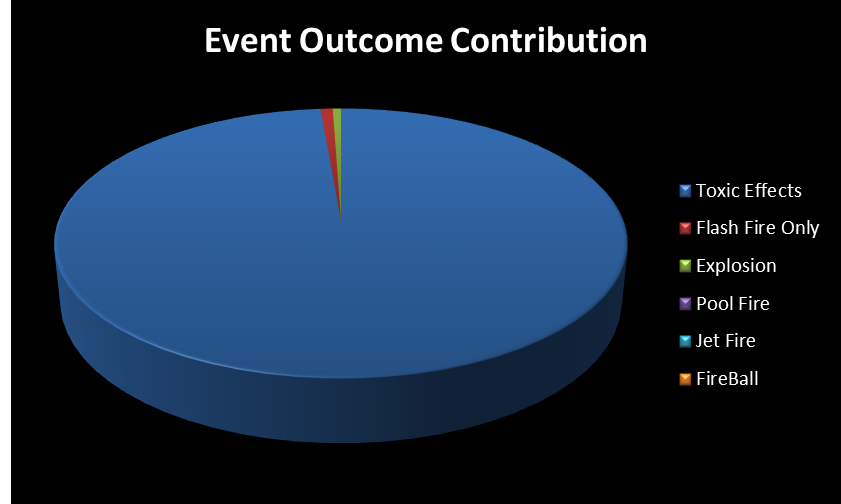

- Consequence modelling using PHAST demonstrated that:

- Toxic effects of chemicals handled were contributed to around 74.6% of the risk

- Both Toxic and flammable effects of chemicals handled were contributed to around 24% of the risk

Figure 1 : Event Outcome Distribution

- As small part of population risks found to be in unacceptable risk region, the study recommends risk reduction measures, and additional good-practice measures to reduce or maintain risk levels.

- Conclusion

The Quantitative Risk Assessment (QRA) study concluded that the risks associated with storage Tanks at Tagros Chemicals India Pvt. Ltd. are ALARP to unacceptable for small part of population, considering the identified loss of containment scenarios and the existing engineering, operational, and emergency safeguards. The study recommended risk reduction measures so that risks can be maintained well within the ALARP region. Overall, the study demonstrates the importance of quantitative risk evaluation and inherently safer design principles in ensuring safe, reliable, and compliant operation of Agrochemical manufacturing facility.