In high-pressure industrial environments, the difference between a safe operation and a catastrophic failure often comes down to the precision of your pressure relief systems. Two of the most common components used are the Pressure Safety Valve (PSV) and the Rupture Disk (RD).

When these two are installed in series, understanding their pressure settings is not just a best practice—it is a critical safety requirement.

The Role of PSVs and Rupture Disks

A Rupture Disk is often installed upstream of a PSV to seal the system against emissions, provide corrosion protection for the valve, and reduce long-term maintenance costs. Together, they act as a vital defense mechanism to release excess pressure and prevent vessel failure.

“The Pressure Safety Hierarchy.”

Setting the Standard: SMPV and API Guidelines

According to the Static and Mobile Pressure Vessels (SMPV) Rules, 2016, safety relief valves must be set to discharge at a pressure no higher than 110% of the vessel’s design pressure (DP) or maximum working pressure (MWP).

Furthermore, API-520 standards provide specific guidance for when these devices are “close-coupled”:

- Close-Coupled Systems: Nominally, the burst pressure and set pressure should be the same.

- Operational Ratios: Forward-acting disks generally require operating pressures at 85-90% of their burst pressure, while reverse-acting disks operate best at 90% or less.

Why the RD Should Burst First

While technical standards often suggest matching pressures, practical industrial safety—including cases like Cohizon Life Sciences—recommends setting the RD burst pressure 5% to 10% lower than the PSV’s set pressure.+1

This specific configuration serves two vital purposes:

- First Line of Defense: It ensures the RD acts first, relieving excess pressure before the PSV is even activated.

- Shock Prevention: It prevents “shock loading” on the PSV, which can occur if the valve is suddenly forced open by high-pressure liquid or gas.

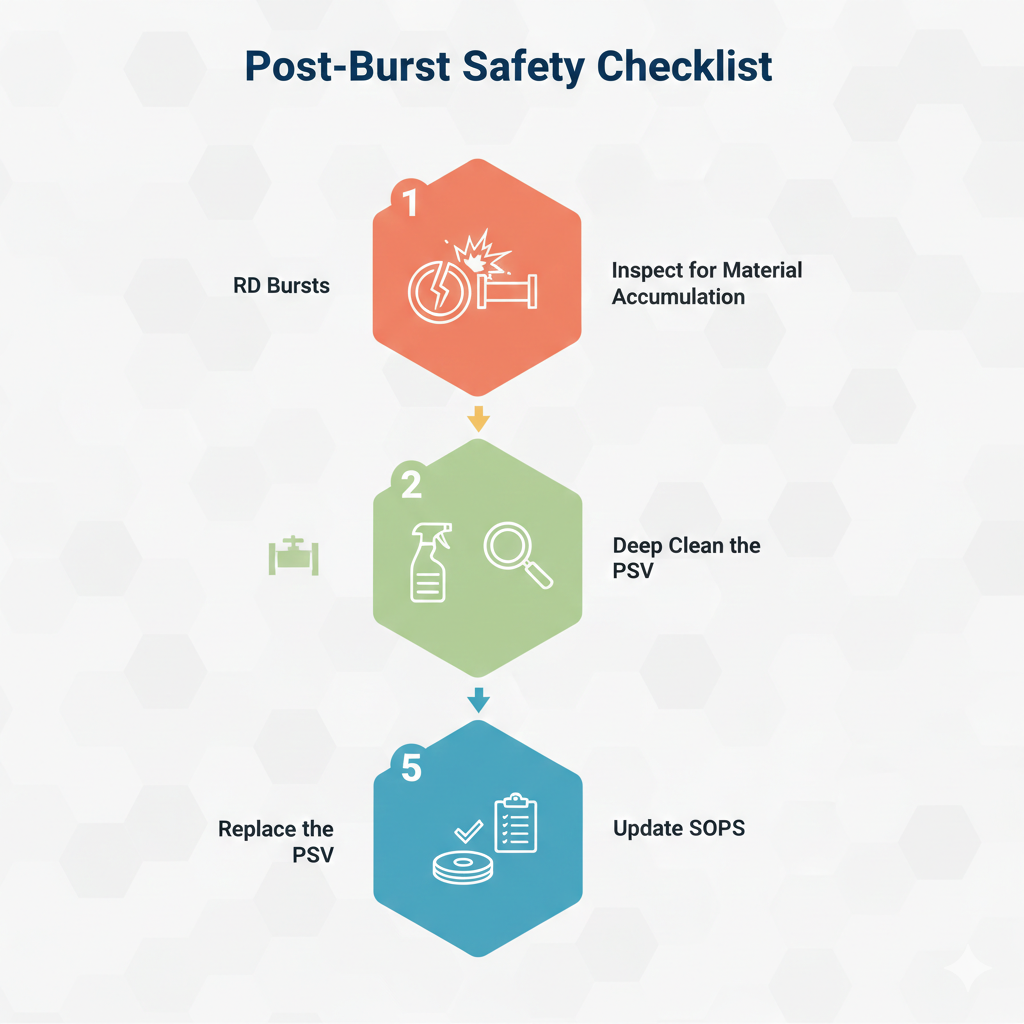

Essential Maintenance and SOPs

A burst rupture disk is a signal for immediate action. If an RD bursts but the PSV does not activate, material can accumulate between the two devices. This buildup can lead to:

- Blockages: Preventing future pressure relief.+1

- Corrosion: Damaging the sensitive internal components of the PSV.+1

It is essential to update your Standard Operating Procedures (SOPs) to require the opening and cleaning of the PSV every time a rupture disk is replaced.+1

Conclusion

Proper coordination between your PSV and Rupture Disk is the backbone of pressure vessel safety. By following API and SMPV guidelines and maintaining a 5-10% pressure differential, you ensure your equipment—and your personnel—remain protected.