1.What is the Objective of HAC?

The purpose of the Hazardous Area Classification study is to determine the extent of the

hazardous areas around equipment handling or storing flammable fluids, combustible fluids and

combustible dusts, both liquid and vapors in terms of Zone 0/20, Zone 1/21, Zone 2/22

The aim of hazardous area classification is to avoid ignition of those releases that may occur from

time to time in the operation of facilities handling flammable liquids and vapors. The approach is

to reduce to an acceptable minimum level the probability of coincidence of a flammable

atmosphere and an electrical or other source of ignition occurring. In Hazardous Area

Classification the extent of the hazardous areas around equipment handling or storing flammable

fluids, both liquid and vapors is determined in terms of Zone 0, Zone 1, and Zone 2. The hazardous

area classification around the equipment handling flammable/explosive dust is determined in

terms of Zone 20, Zone 21, and Zone 22.

2.What is the Scope of HAC?

The Scope of HAC is as follows: –

The Hazardous area classification is carried out as per:

∙Classification of the Hazardous area for explosive dust is carried out as per IEC 60079-10-2

∙Classification of the Hazardous area for flammable liquids/ gases/ vapors is carried out as per

IEC 60079-10-1

3.What reference is commonly used for HAC Methodology?

The reference used for HAC study is as follows:

∙Draft Version of EI15 Edition 4– Model Code of Safe Practice – Area Classification Code for

Installations Handling Flammable Fluids. Energy Institute 2015. 3.

∙ EI15 Edition 3– Model Code of Safe Practice – Area Classification Code for Installations

Handling Flammable Fluids. Energy Institute 2005.

∙IEC 60079-10-1 Explosive atmospheres Part 10-1: Classification of areas – Explosive gas

atmospheres

∙IEC 60079-10-2 Explosive atmospheres Part 10-2: Classification of areas – Explosive dust

atmospheres

∙Any other National and International Guideline Recommended by Client.

4.What is the order of precedence for HAC Study guideline?

The order of precedence for HAC study is as follows:

∙IEC 60079-10-1 Explosive atmospheres Part 10-1: Classification of areas – Explosive gas

atmospheres

∙IEC 60079-10-2 Explosive atmospheres Part 10-2: Classification of areas – Explosive dust

atmospheres

∙Draft Version of EI15 Edition 4– Model Code of Safe Practice – Area Classification Code for

Installations Handling Flammable Fluids. Energy Institute 2015. 3.

∙ EI15 Edition 3– Model Code of Safe Practice – Area Classification Code for Installations

Handling Flammable Fluids. Energy Institute 2005.

UAE regulation

∙National & International reference books.

5.What is the methodology for HAC Study?

The methodology for HAC Study is as follows:

∙Data collection

∙MSDS Sheet Preparation

∙Process step and Representative Chemical sheet preparation

∙Client Approval for HAC Schedule preparation

∙HAC Schedule

∙Draft Report

∙Client Approval for HAC marking

∙HAC marking

∙Comments incorporation along with CRS (Comment Resolution Sheet)

∙Final Report

6.What are the Different Types of Grades of Release?

Three types of grades of release are as follows

∙Continuous Grade release (C): A release that is continuous or nearly so, or that occurs

frequently and for short periods.

∙Primary Grade release (P): A release that is likely to occur periodically or occasionally in

normal operation, that is, a release which, in operative procedures, is anticipated to occur.

∙Secondary grade release (S): A release that is unlikely to occur in normal operation and, in any

event, will do so only infrequently and for short periods, that is, a release which, in operating

procedures, is not anticipated to occur.

7.What are the Different Types of Class of the Fluid?

Three types of class of fluid are as follows:

Flammable Liquids vary in volatility and have a flash point below 93 °C and a Vapor Pressure not

exceeding 2.81 kg/cm2 at 37.8 °C. These are divided into three classes, as follows,

∙Class A : Flammable liquids having flash point below 23 °C

∙Class B : Flammable liquids having flash point 23 °C and above but below 65 °C

∙Class C : Flammable liquids having flash point 65 °C and above but below 93 °C

8.What are the steps for HAC study?

The steps for HAC Study are as follows:

∙Identification of the Point Source or Source of Release

∙Determine the Grade of Release

∙Determine the Class of the Fluid

∙Determine the Ventilation Requirements

∙Establish Zone Classification

∙Determine Hazard Radii

∙Determine Hazardous Area

To enable selection of electrical equipment’s appropriate to the zone classification, the

apparatus sub group and temperature class is then determined based on the flammable

substances that can be released.

9.According to IEC guidelines in hazardous area classification, what are the different types of degree of dilution recognized?

Following degree of dilution is recognized in HAC Study as per IEC Guidelines.

The following three degrees of dilution are recognized:

∙High dilution (H): The concentration near the source of release reduces quickly and there will

be virtually no persistence after the release has stopped.

∙Medium dilution (M): The concentration is controlled resulting in a stable zone boundary, whilst

the release is in progress and the explosive gas atmosphere does not persist unduly after the

release has stopped.

∙Low dilution (L): There is significant concentration whilst release is in progress and/or significant

persistence of a flammable atmosphere after the release has stopped.

10.What are the different zones defined by IEC for hazardous areas, and how are they classified?

Different Zones defined by IEC for hazardous areas are follows:

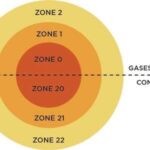

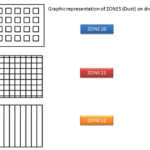

IEC defines zones based on the frequency and duration of the presence of hazardous

substances. Zones include Zone 0 (continuous presence), Zone 1 (intermittent presence), and

Zone 2 (occasional presence) for gases and vapors, and Zone 20 (continuous presence), Zone 21

(intermittent presence), and Zone 22 (occasional presence) for combustible dusts.

∙Zone 0 Areas: An area in which an explosive gas atmosphere is present continuously or is

present for long periods. Examples are vapor space above closed process vessels, storage

tanks or closed containers, areas containing open tanks of volatile, flammable liquid.

∙Zone 1 Areas: An area in which an explosive gas atmosphere is likely to occur in normal

operation

∙Zone 2 Areas: An area in which an explosive gas atmosphere is not likely to occur in normal

operation and if it does occur it will exist for a short period only

∙Zone 20: A place in which an explosive atmosphere, in the form of a cloud of combustible dust

in air, is present continuously, or for long periods or frequently for short periods

∙Zone 21: A place in which an explosive atmosphere, in the form of a cloud of combustible dust

in air, is likely to occur occasionally in normal operation.

∙Zone 22: A place in which an explosive atmosphere, in the form of a cloud of combustible dust

in air, is not likely to occur in normal operation but, if it does occur, will persist for a short period

only.

11.What are the documents required for the HAC Study?

The documents required for the HAC Study include the following:

∙Scope of work

∙Approved P&IDs

∙List of Chemicals

∙Process design basis

∙Hazardous inventories and their SDS

∙Process description

∙MSDS or Chemical properties of RM & FG

∙Equipment Design and Operating Condition /MOC

∙Equipments & Details

∙Layout & plot plan

12.How does the availability of ventilation influence the determination of zone type in hazardous area classification?

The availability of ventilation plays a crucial role in the presence or formation of an explosive

gas atmosphere, thus affecting the classification of hazardous zones. Three levels of ventilation

availability are considered:

∙Good (G): Ventilation is continuously present.

∙Fair (F): Ventilation is expected during normal operation, with occasional short discontinuities.

∙Poor (P): Ventilation does not meet the standards of fair or good, but long periods of

discontinuities are not expected.

13.What are documents deliverables for HAC Study?

The documents deliverables for HAC Study are as follows:

∙Executive Summary

∙Document Review

∙Submission of terms of reference

∙HAC Methodology

∙HAC Schedule

∙HAC Marked Layout

∙Comments Resolution sheets

∙Reference

∙List of tables

∙List of appendix

14.What are some common industry sectors that require hazardous area classification?

Following industrial sectors require HAC

Common sectors include oil and gas, chemical processing, pharmaceuticals, food and

beverage, mining, and manufacturing where the presence of flammable or combustible

substances poses a risk of ignition and explosion.

15.Which software will be used for the HAC study?

Following software will be used for HAC marking:

∙AutoCAD

16.What are the different guidelines for HAC study?

Different guidelines used for HAC study are as follows:

∙NFPA-497 Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified)

Locations for Electrical Installations in Chemical Process Areas.

∙NFPA–499 (Classification of Combustible Dusts and of Hazardous (Classified) Locations for

Electrical Installations in Chemical Process Areas)

∙Classification of the Hazardous area for explosive dust is carried out as per IS 61241

∙Classification of the Hazardous area for flammable liquids/ gases/ vapors is carried out by IS

5572

17.What are the consequences of inadequate hazardous area classification?

Inadequate HAC Study can lead to following consequences

Inadequate classification may lead to increased risk of ignition and explosion, equipment failure,

injury to personnel, damage to property, environmental pollution, and legal liabilities,

underscoring the importance of following IEC guidelines for hazardous area classification.

18.What is the Objective of HAZOP?

The objective of HAZOP is as follows: –

The purpose of HAZOP Study is to identify the hazard and operability problems and to reduce the probability and consequences of an incident in the process facilities that would have a detrimental impact to the personnel, plant, properties, environment and company reputation.

19.What is the Scope of HAZOP?

The Scope of HAZOP is as follows:-

HAZOP studies shall be applied to all new, continuous process designs, including package units & utility systems. However, the applicability of HAZOP during the various life cycle phases of the system is described below as per IEC 61882 STD:-

Conceptual Design phase – In this phase, the design concept and major system components are decided, but the design and documentation to conduct the HAZOP do not exist.

Front End Engineering Design (FEED) phase – During this phase, the design is developed, methods of operation are decided and documentation is prepared.

Detail Design / Engineering Phase – HAZOP Study during this phase shall be conducted after finalizing the detailed design, before the issue of important engineering drawings and documentation including P & IDs, C&E etc.,

Installation and Commissioning Phase – In case where the proper operation sequences and instructions are critical and the commissioning and operation of the system can be hazardous

Operational Phase- HAZOP Study shall be considered during Operational Phase before implementing any changes to the existing system

20.What reference is commonly used for HAZOP Study?

The commonly used reference for HAZOP studies is as follows:

IEC 61882: 2016 Hazard and Operability Studies (HAZOP Studies) Application Guide

21.What is the order of precedence for HAZOP Study guidelines?

The commonly used order of precedence for HAZOP studies is as follows:

IEC 61882: 2016 Hazard and Operability Studies (HAZOP Studies) Application Guide,

As per Client Guidelines and

National & International reference books.

22.What is the methodology for HAZOP Study?

The methodology for HAZOP Study is as follows:-

Data collection

Pre-HAZOP Workshop Preparation

HAZOP Workshop / Site visit

Draft Report

Comments incorporation along with CRS (Comment Resolution Sheet)

Final Report

23.What are the steps for the Pre-HAZOP Workshop Preparation?

The steps for the Pre-HAZOP Workshop Preparation are as follows:-

Gather Information

MSDS Sheet Preparation

Node Marking on P&ID

Client Approval for Node Marking

Discussion with Client

Worksheet Preparation

24.What are the documents required for the HAZOP Study?

The documents required for the HAZOP Study include the following:

Scope of work

Approved P&IDs

Process design basis

Approved PFDs

Approved Cause & Effect Diagram

Operating & Control Philosophy Document

Hazardous inventories and their SDS

Process description

MSDS or Chemical properties of RM &FG

Safety Test Report

Previous HAZOP Report

Equipment Design and Operating Condition /MOC

25.What are the steps for HAZOP Study?

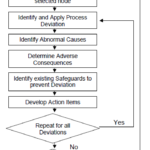

The steps for conducting a HAZOP Study are outlined below:

Select a Node, which contains an elementary unit of the plant.

Define the Node design intent and process conditions.

Apply the first parameter to the node such as Flow, Pressure, Temperature, Level, Composition, etc.

Apply suitable Guide Word such as more, less, etc. to obtain a Deviation of the Parameter.

Identify the potential and credible Causes associated with the Deviation by brainstorming.

Assess the Consequences of each cause.

Identify Safeguards included in the design to prevent and/or mitigate the hazard.

Agree a Recommendation for action if the existing safeguards are found to be inadequate. If an immediate solution is available and acceptable to the team, the modification is recorded in the HAZOP worksheet and HAZOP master P&ID will be marked up accordingly. Where solutions are unlikely to be derived without a technical evaluation, the Chairman will refer the problem for separate assessment.

Repeat the above procedures to the next guideword (move to step 4) until these guidewords have been completed.

Repeat the above procedures to the next parameter (move to step 3) until these parameters have been completed.

Move to the next node (go step 1) of the process system. All process systems will be examined

26.What are documents deliverables for HAZOP Study?

The document deliverables for the HAZOP Study are as follows:

Executive Summary

Document Review

Submission of terms of reference

HAZOP Methodology

Risk Ranking Matrix

Participant Attendance sheet

Node List

Executive Summary

HAZOP Worksheet

Comments Resolving sheets

Mark Up P&ID’s

Reference

List of tables

List of appendix

27.What are Fundamental Assumption for HAZOP Study?

The Fundamental Assumption for the HAZOP Study are as follows:

The potential for hazard and operability problems does not exist when the process is operating within its design envelope.

Cause shall be in the same node; consequences can be anywhere in the process.

Everything is running well and then “SOMETHING” happens

28.Which software will be used for the HAZOP study?

The software to be used for the HAZOP study is as follows:

PHA Pro version 8.19 software.

29.What are Exclusion for HAZOP Study?

The Exclusion for the HAZOP study is as follows:

Simultaneous occurrence of two unrelated incidents

Operator’s negligence(Except common human error)

Simultaneous failure of more than one independent protective device

Natural calamity( Flood, Earthquake) except where it is design case

External fire/escalation

30.What are the considerations Of Safeguards for HAZOP Study?

The Consideration Of Safeguards for the HAZOP study is as follows:

Following is deemed as protection/safeguard

Interlock/ Shutdown system/ Trip

Alarm system for operator action

Sample monitoring system

Mechanical monitoring device

Operating instructions and operating manual

Indicator and status signal gauges when the associated system in operator

31.What is Study Nodes?

The definition of study node is as follows:

The Node is the portion of the plant subject to the study, where single or limited process

functions are assigned.

32.What is Parameter in HAZOP Study?

The definition of parameters in HAZOP Study is as follows:

The usual parameters applied to all nodes are Pressure, Temperature and Composition. Additional parameters are Flow, Level, etc. These additional parameters may be required by the nature of each node.

33.What are Guidewords in HAZOP Study?

The definition of guidewords in HAZOP Study is as follows:

The Guidewords, such as More, Less, Reverse and Other Than, are combined with Parameters, Flow, Temperature and Pressure to derive meaningful deviations.

34.What is Deviation in HAZOP Study?

The meaning of deviation in HAZOP Study is as follows:

Deviations consist of a GUIDEWORD + PARAMETER

35.What information does the executive summary of a HAZOP Report typically include?

The information which are typically included in Executive summary is as follows:

The executive summary of a HAZOP (Hazard and Operability Study) Report provides a overview of the study’s objectives, methodology, key findings, and recommendations.

It typically includes:

Introduction: Briefly outlines the purpose of the HAZOP study and the systems/processes analyzed.

Methodology: Describes the approach used in the study, including the team composition, brainstorming sessions, and node identification.

Key Findings: Summarizes the significant deviations or hazards identified during the study, along with their potential consequences.

Recommendations: Provides high-level recommendations for mitigating the identified hazards and improving the safety and operability of the system.

Conclusion: Concludes with a summary of the overall importance of the study and any next steps.

36.How are recommendations typically classified?

Recommendations are classified as follows:

Recommendations in HAZOP (Hazard and Operability Study) are typically classified based on their urgency, impact, and status. Here are the common classifications:

Category A: Urgent Actions- Recommendations that require immediate attention and should be implemented before the system is commissioned or operated. These actions are critical for preventing severe consequences or hazards.

Category B: Important Actions- Recommendations that are important for safety or operability but can be implemented after the system is commissioned. These actions should be completed within a specified timeframe to mitigate risks effectively.

Category C: General Improvements- Recommendations that focus on enhancing overall plant performance, efficiency, or reliability. These actions typically have no immediate safety implications but contribute to long-term improvements.

Category D: Pending Actions- Recommendations for which a final decision or conclusion is pending. These actions may require further evaluation or discussion before being classified as Category A or B recommendations.

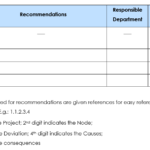

37.What is the format of Recommendation Table and legends for place used?

The format used for Recommendation Table and legends is as follows:

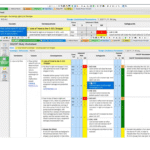

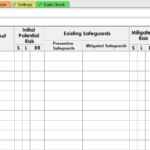

38.What is the HAZOP Worksheet format?

The format used for HAZOP Worksheet is as follows:

39.What is the Comment Resolution Sheet?

The meaning of Comment Resolution Sheet (CRS) is as follows:

A comment resolution sheet is a document used to track and address comments, feedback, or issues raised during a review process, audit, or evaluation.

40. What is the Objective of HAC?

The objective of HAC is as follows:

The purpose of the Hazardous Area Classification study is to determine the extent of the hazardous areas around equipment handling or storing flammable fluids, combustible fluids and combustible dusts, both liquid and vapors in terms of Zone 0, Zone 1, Zone 2 and Division 1 and Division 2

The aim of hazardous area classification is to avoid ignition of those releases that may occur from time to time in the operation of facilities handling flammable liquids and vapors. The approach is to reduce to an acceptable minimum level the probability of coincidence of a flammable atmosphere and an electrical or other source of ignition occurring. In Hazardous Area Classification the extent of the hazardous areas around equipment handling or storing flammable fluids, both liquid and vapors is determined in terms of Zone 0, Zone 1, and Zone 2. The hazardous area classification around the equipment handling flammable/explosive dust is determined in terms of Division 1, Division 2.

41.What is the Scope of HAC?

The Scope of HAC is as follows: –

The Hazardous area classification is carried out as per:

Classification of the Hazardous area for explosive dust is carried out as per NFPA 499

Classification of the Hazardous area for flammable liquids/ gases/ vapors is carried out by NFPA 497

42.What reference is commonly used for HAC Study?

The reference used for HAC study is as follows:

NFPA-497 Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas.

NFPA–499 (Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas)

43.What is the order of precedence for HAC Study?

The order of precedence for HAC study is as follows:

NFPA 497/ NFPA 499

As per Client Guidelines

Other international standards

44.What is the methodology for HAC Study?

The methodology for HAC Study is as follows:

Data collection

MSDS Sheet Preparation

Process step and Representative Chemical sheet preparation

Client Approval for HAC Schedule preparation

HAC Schedule

Draft Report

Client Approval for HAC marking

HAC marking

Comments incorporation along with CRS (Comment Resolution Sheet)

Final Report

45.Different Types of Grade of Release?

Three types of grade of release are as follows:

Continuous Grade release (C): A release that is continuous or nearly so, or that occurs frequently and for short periods.

Primary Grade release (P): A release that is likely to occur periodically or occasionally in normal operation, that is, a release which, in operative procedures, is anticipated to occur.

Secondary grade release (S): A release that is unlikely to occur in normal operation and, in any event, will do so only infrequently and for short periods, that is, a release which, in operating procedures, is not anticipated to occur.

46.Different Types of Class of the Fluid?

Three types of class of fluid are as follows:

Flammable Liquids vary in volatility and have a flash point below 93 °C and a Vapor Pressure not exceeding 2.81 kg/cm2 at 37.8 °C. These are divided into three classes, as follows,

Class A : Flammable liquids having flash point below 23 °C

Class B : Flammable liquids having flash point 23 °C and above but below 65 °C

Class C : Flammable liquids having flash point 65 °C and above but below 93 °C

47.Area Classification (As per NFPA 497).

Area classification as per NFPA is as follows:

Class-1 Zone 0 Areas: A Class I, Zone 0 location is a location that meets the following conditions:

Ignitable concentrations of flammable gases or vapors that are present continuously

Ignitable concentrations of flammable gases or vapors that are present for long periods of time.

Class I, Zone 1. Areas: A Class I, Zone 1 location is a location that meets the following conditions:

Ignitable concentrations of flammable gases or vapors that are likely to exist under normal operating conditions.

Ignitable concentrations of flammable gases or vapors that may exist frequently because of repair or maintenance operations or because of leakage.

Class I, Zone 2 Areas: A Class I, Zone 2 location is a location that meets the following conditions:

Ignitable concentrations of flammable gases or vapors that are not likely to occur in normal operation, and if they do occur, they will exist only for a short period.

48.What are the steps for HAC Study?

The steps for HAC Study are as follows:

Methodology for Flammable Liquid and vapours:

Review Process Flow diagram

Prepare separate table for liquid and solid chemical along With flammable/combustible Properties

Classification of material as per NFPA-497

Selecting the Appropriate Classification Diagram

Determine the Zone classification

Determine Extent of the Classified Location

Review and recommendation

To enable selection of electrical equipment appropriate to the zone classification, the apparatus sub group and temperature class is then determined based on the flammable substances that can be release.

Methodology for Combustible dusts

Need For Classification

Facility information & history

Classification of material as per NFPA-499

Selecting the Appropriate Classification Diagram

Determine the Zone classification

Determine Extent of the Classified Location

Review and recommendation

To enable selection of electrical equipment appropriate to the zone classification, the apparatus sub group and temperature class is then determined based on the flammable substances that can be release.

49.What are the documents required for the HAC Study?

The documents required for the HAC Study include the following:

Scope of work

Approved P&IDs

List of Chemicals

Process design basis

Hazardous inventories and their SDS

Process description

MSDS or Chemical properties of RM & FG

Equipment Design and Operating Condition /MOC

Equipments & Details

Layout & plot plan

50.What are documents deliverables for HAC Study?

The documents deliverables for HAC Study are as follows:

Executive Summary

Document Review

Submission of terms of reference

HAC Methodology

HAC Schedule

HAC Marked Layout

Comments Resolution sheets

Reference

List of tables

List of appendix

51.Which software will be used for the HAC study?

Following software will be used for HAC marking:

AutoCAD

52.What are the different guidelines for HAC study?

Different guidelines used for HAC study are as follows:

IEC 60079-10-1 Explosive atmospheres Part 10-1: Classification of areas – Explosive gas atmospheres

IEC 60079-10-2 Explosive atmospheres Part 10-2: Classification of areas – Explosive dust atmospheres

Draft Version of EI15 Edition 4– Model Code of Safe Practice – Area Classification Code for Installations Handling Flammable Fluids. Energy Institute 2015. 3.

EI15 Edition 3– Model Code of Safe Practice – Area Classification Code for Installations Handling Flammable Fluids. Energy Institute 2005.

IS 61241- “Electrical Apparatus for Use in the Presence of Combustible Dust – Code of Practice”

IS 5572- “Code of Practice for Electrical Installations of Industrial Establishments: Part 1 General Aspects”

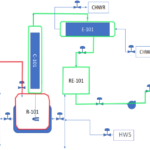

53.How different Zones of HAC are graphically represented?

Graphical representation of HAC Zones are as follows:

54.What is the Comment Resolution Sheet?

The meaning of Comment Resolution Sheet (CRS) is as follows:

A comment resolution sheet is a document used to track and address comments, feedback, or issues raised during a review process, audit, or evaluation.